1C:ERP for India

ERP for Enterprises

All-in-One ERP solution for automation of business processes in Medium and Large Enterprises.

1C:ERP is powered with 1C:Enterprise

Procurement

-

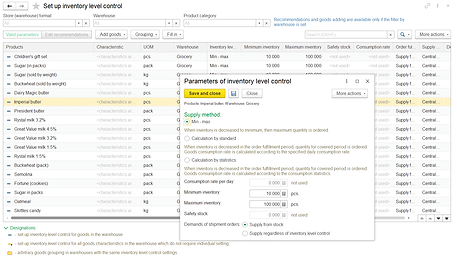

Manage inventory stock balance and production demand

-

Automatically generate POs upon min/max stock settings and production/sales demands statistics including shipping leg

Warehouse and Inventory

-

Create and manage graded warehouse structure, storage bins

-

Manage multiple warehouses

-

Use batches, series, expiration dated for Your inventory

-

Control Your stock level using multiple methods

-

Use delivery tools

Production Management

-

Enjoy visual presentation of the product’s structure

-

Use resource specifications

-

Two level production plan: main and local dispatcher

-

Use operational, interval and “Drum-Buffer-Rope” scheduling

-

Plan “bottleneck” production areas

-

Manage priorities (VIP orders)

-

Calculate time needed for transportation of inventory and in-process queue

-

Forecast the whole process

-

Dispatch production on inter-workshop and intra-workshop levels

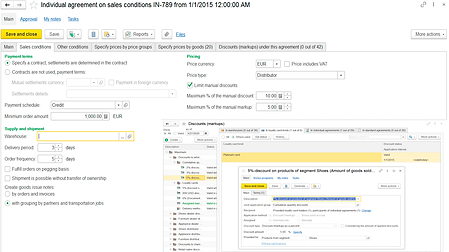

Sales Management

-

Manage customer orders subject to standard and individual agreements on sales conditions

-

Organize clients’ self-service

-

Manage trade representatives

-

Monitor the condition of the sales processes

-

Configure price-lists with inventory information

-

Use various pricing and discounts based on different conditions

-

Monitor sales processes using sales pipeline and sales funnel

-

Use sales planning and forecasts

-

Create sales reports by company/client/product/department/employee

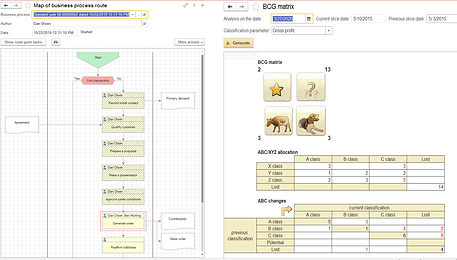

CRM and Marketing

-

Track interactions with customers

-

Use business-process road maps to automate business-processes

-

Maintain customers' loyalty with rewards, membership cards, flexible discount system

-

Use BCG Matrix

-

Perform ABC/XYZ analysis

-

Use grievance redressal mechanism

-

Evaluate employees' performance

Budgeting

-

Manage your budgets using extra parameters

-

Draft Your budgeting scenarios

-

Forecast Your financial indicators

-

Perform targets and goals achievement analysis

Net Cost Calculation and Financial Result

-

Classify resources used in production

-

Allocate costs to different activities

-

Count expenses in terms of cost and quantity

-

Separate cost by orders

-

Perform quantity resource accounting for unfinished production

-

Use different methods to distribute expenses (manufacturing costs/spheres of activities/future expences)

-

Configure reports for financial results analysis

Maintenance And Repair

-

Plan maintenance of Your machinery to minimise downtime

-

Plan repairs and control repair orders from machinery operators

-

Keep track of equipment output volume

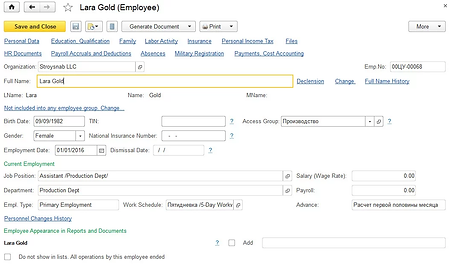

Payroll & HR Management

-

Plan the demand for personnel

-

Manage employees' motivation

-

Organise personnel documentation: employment, vacations, staff movements, dismissals

-

Use various payroll schedules

-

Calculate remuneration in accordance with employees' effectiveness